In the realm of wireline cable maintenance, Corelube Equipment stands at the cutting edge of technology with its latest wire cleaner as well as air wiper technologies. Wireline cables are utilized in a myriad of industries, including oil and gas, mining, and telecoms. They are frequently exposed to harsh environmental conditions and must be able to meet the most stringent operational demands. To keep the quality and durability of wireline cables is vital to maintain and shield them from wear and corrosion. Corelube Equipment redefined cable maintenance by providing cutting-edge solutions. It has created new standards for maintenance.

Corelube’s innovative technology for cleaning wire is an innovation in cable maintenance. By taking on the vital job of cleaning wire, Corelube Equipment has revolutionized the way to preserve wireline cables. The accumulation of dirt, debris, and contaminants on wireline cables could weaken their structural integrity and performance. Corelube’s solutions for cleaning wires are designed to eliminate dirt, particles, and contaminants. This guarantees that cables are clear of harmful deposits that could cause wear and corrosion.

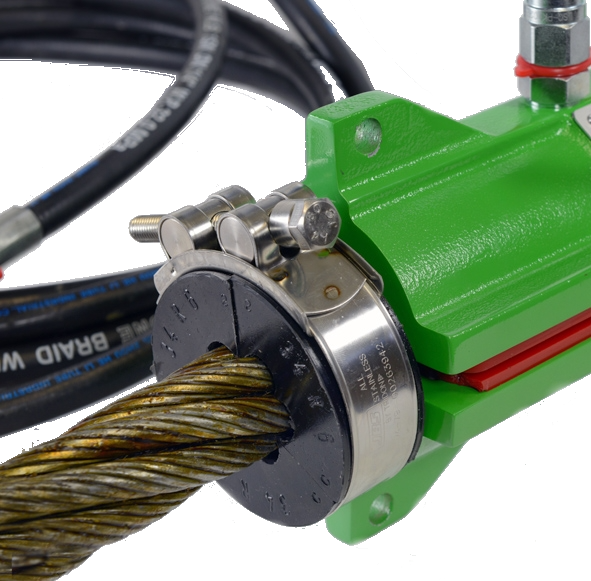

Corelube’s air wiper technology is not only used to clean wires, but it also shields wireline cables from environmental elements and wear. Air wipers build an environment that shields cables from moisture, dust, and other elements. Corelube Equipment improves the resilience and endurance of wireline cables by using air wipers.

The combination of Corelube’s wire cleaner and air wiper technologies redefines the process of maintaining wireline cables with a range of comprehensive solutions to preserve the performance and integrity of these crucial components. Corelube’s engineering expertise can be seen in its capability to address the two issues that arise from cleaning the wire and protecting it against wear and corrosion. This results in a new standard of care for cables that increases the longevity of cables and ensures the safe operation of these cables for many industrial applications.

Corelube’s solutions for cleaning wire allow for optimizing the performance of wireline cables in demanding environments. Wireline cables, whether they are used in mining operations, offshore drilling, or for infrastructures used in telecom, are subject to extreme conditions. They require reliable maintenance solutions. Corelube’s innovative approach to wireline cable management allows industries to attain higher efficiency in operation and reliability, which reduces maintenance and downtime costs that come with cable malfunctions.

Corelube’s technology of wire cleaner and air wiper provides a proactive approach to wireline cable maintenance. These tools prevent premature wear and corrosion before they affect the strength of the structure. Regularly cleaning and protecting actions can prolong the life of wireline cables, and reduce the need for expensive repairs and replacements. Corelube Equipment is committed to proactive maintenance that is aligned with the needs of the industry for efficient and sustainable solutions.

Corelube’s air wiper and wire cleaner technologies have an enormous impact that goes far beyond simple maintenance. They also impact the safety of our environment as well as our lives. Wireline cables play an important function in a variety of industrial processes. Their reliability is essential for safety and the environment. Corelube technologies guarantee the purity and safety of wireline cables. This complies with industry standards and regulations.

In the end, Corelube Equipment’s advanced wire cleaner and air wiper technologies have transformed the world of cable care for wireline cables, offering comprehensive solutions for cleaning wire and protecting cables from wear and corrosion. The fusion of these advanced technologies has elevated the standard of maintenance for wireline cables aiding industries in achieving greater efficiency, reliability, and security. Corelube Equipment’s focus on engineering and proactive maintenance is driving the development of cost-effective, sustainable solutions for a broad range of industrial applications.